-

دستگاه بسته بندی کیسه

-

دستگاه بسته بندی گرانول

-

دستگاه بسته بندی مایعات

-

دستگاه بسته بندی پودر

-

دستگاه بسته بندی Mini Doypack

-

دستگاه بسته بندی چای کیسه ای

-

دستگاه بسته بندی قهوه

-

دستگاه بسته بندی عمودی

-

دستگاه بسته بندی جریان

-

دستگاه بسته بندی کیسه ای ایستاده

-

دستگاه بسته بندی وکیوم روتاری

-

ماشین پر کننده

-

دستگاه بسته بندی Doypack افقی

-

کیف از پیش ساخته شده

-

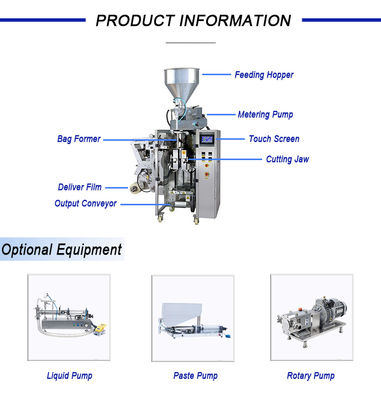

لوازم جانبی دستگاه بسته بندی

-

ماشین پر کردن و پوشاندن

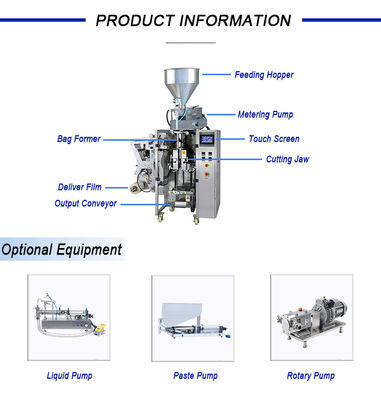

دستگاه بستهبندی عمودی خمیر مایع با کیسههای چهار طرفه مهر و موم شده فیلم کاغذی/پلاستیکی پرکن و آببندی خودکار 220 ولت/380 ولت

برای نمونه ها و کوپن های رایگان با من تماس بگیرید.

WhatsApp:0086 18588475571

ویچت: 0086 18588475571

اسکایپ: sales10@aixton.com

اگر شما هر گونه نگرانی دارید، ما 24 ساعت کمک آنلاین ارائه می دهیم.

x| تایپ کنید | ماشین بسته بندی چند منظوره | گارانتی | 12 ماه |

|---|---|---|---|

| برنامه | مواد غذایی، مواد شیمیایی، کالا، پزشکی، ماشین آلات و سخت افزار | نوع بسته بندی | کیف، کیف |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

دستگاه بستهبندی خمیر مایع عمودی با کیسههای مهر و موم شده چهار طرفه فیلم کاغذی/پلاستیکی پرکن و آببندی خودکار 220 ولت/380 ولت

دستگاه بستهبندی عمودی برای کره یک دستگاه بستهبندی خودکار است که بهطور خاص برای مواد غذایی چسبناک و نیمهجامد مانند کره، مارگارین و پنیر طراحی شده است. این دستگاه از روش «کیسهسازی عمودی» استفاده میکند، به این معنی که از رول فیلم اولیه، دستگاه مستقیماً مجموعهای از اقدامات از جمله کیسهسازی، پر کردن، آببندی و برش را تکمیل میکند و در نهایت محصولات نهایی بستهبندی شده جداگانه را خروجی میدهد.

I. اصل کار

1. کیسهسازی: رولهای فیلم بستهبندی (مانند فیلم کامپوزیت فویل آلومینیومی یا فیلم کامپوزیت چند لایه) روی دستگاه نصب میشوند. فیلم از یک دستگاه کشش و غلتکهای راهنما عبور میکند و به واحد شکلدهی کشیده میشود. واحد شکلدهی فیلم مسطح را به شکل استوانهای در میآورد.

2. آببندی طولی: کنارههای فیلم با استفاده از یک دستگاه آببندی حرارتی به صورت طولی آببندی میشوند و یک کیسه استوانهای پیوسته تشکیل میدهند.

3. آببندی و برش عرضی: یک جفت فک آببندی عرضی همزمان هر دو انتهای کیسه استوانهای را با حرارت آببندی میکند. مهر و موم عرضی بالایی به عنوان مهر و موم بالایی کیسه فعلی عمل میکند و مهر و موم عرضی پایینی به عنوان مهر و موم پایینی کیسه بعدی عمل میکند. همزمان با آببندی عرضی، یک برش، کیسههای جلو و عقب را بین دو مهر و موم جدا میکند.

4. پر کردن: در فواصل بین حرکات مکانیسم آببندی افقی، مقدار اندازهگیری شدهای از کره از طریق نازل پرکننده بالایی به کیسههای آببندی شده پایینی تزریق میشود. معمولاً از یک پمپ پیستونی برای پر کردن استفاده میشود که آن را برای جابجایی مواد با ویسکوزیته بالا ایدهآل میکند.

5. خروجی: پس از پر کردن و آببندی بالایی، کیسهها بریده شده و به یک نوار نقاله یا سبد جمعآوری میافتند.

کل این فرآیند توسط یک PLC (کنترلکننده منطقی قابل برنامهریزی) و سیستم سروو بهطور دقیق کنترل میشود و به تولید خودکار، پیوسته و با سرعت بالا دست مییابد.

II. ویژگیهای اصلی

1. راندمان بالا: درجه بالایی از اتوماسیون؛ سرعت بستهبندی میتواند به دهها تا صدها کیسه در دقیقه برسد که بسیار فراتر از بستهبندی دستی است.

2. دقت بالا: پمپهای پیستونی دقیق یا پر کردن سروو-درایو وزن ثابتی را در هر کیسه کره تضمین میکنند و استانداردهای ملی اندازهشناسی را برآورده میکنند.

3. بستهبندی زیبا: مهر و مومهای ایمن و صاف، شکل کیسه یکنواخت، افزایش کیفیت محصول.

4. کاهش آلودگی: فرآیند کاملاً خودکار تماس انسان با مواد را به میزان قابل توجهی کاهش میدهد و استانداردهای بهداشت و ایمنی مواد غذایی (مانند GMP، HACCP) را برآورده میکند.

5. انعطافپذیری: با تغییر دستگاههای شکلدهی و نازلهای پرکننده مختلف، میتواند با کیسههای بستهبندی با اندازهها و شکلهای مختلف (مانند مهر و موم پشتی، مهر و موم سه طرفه و مهر و موم چهار طرفه) سازگار شود.

6. صرفهجویی در نیروی کار: معمولاً یک نفر برای کار با یک دستگاه مورد نیاز است که مسئول تغذیه و نظارت است و هزینههای نیروی کار را به میزان زیادی کاهش میدهد.

7. سازگاری گسترده مواد: علاوه بر کره، با کمی تنظیمات، میتوان از آن برای بستهبندی مربا، خمیر، عسل، خمیر لوبیا و سایر محصولات با ویسکوزیته مشابه نیز استفاده کرد.

III. محصولات و صنایع قابل اجرا

1. محصولات اصلی: کره، مارگارین، پنیر، پنیر خامهای، کنسانتره بستنی، خمیر دندان، پماد و غیره.

2. صنایع اصلی: صنعت لبنیات، صنعت پخت، کارخانههای فرآوری مواد غذایی، زنجیره تامین غذا، صنایع شیمیایی و دارویی.

مشخصات دستگاه:

|

سرعت بستهبندی |

5 - 40 کیسه در دقیقه |

| اندازه کیسه (میلیمتر) | L100 - 250, W30 - 160 |

| حداکثر عرض فیلم (میلیمتر) | 320 |

| ضخامت کیسه (میلیمتر) | 0.04 - 0.09 |

| محدوده پر کردن | 10 - 100 گرم |

| جنس کیسه | BOPP / CPP, PET / AL / PE و غیره |

| هوای فشرده | 0.8MPa, 0.5m3/min |

| برق | 4.5KW |

| ولتاژ | 220v 50/60Hz |

| اندازه واحد (میلیمتر) | 1350*1120*1250 |

| وزن واحد (کیلوگرم) | 500 |

| نوع کیسه | کیسه مهر و موم شده 4 طرفه (گزینه: کیسه مهر و موم شده 3 طرفه) |

(ما میتوانیم خدمات سفارشی انحصاری را با توجه به نیازهای شما ارائه دهیم!)

![]()

![]()

![]()

Application:

آبمیوه، مربا، بستههای سس، کچاپ، سس سالاد، سس میوه، شامپو، سس سویا و غیره.

خدمات پس از فروش:

1. ارائه دفترچه راهنما/ویدیو برای نصب، تنظیم، راهاندازی و نگهداری دستگاه برای استفاده شما.

2. اگر مشکل قابل حل نیست، ارتباط تلفنی 24 ساعته یا ارتباط آنلاین رو در رو در دسترس است.

3. مهندسان SUNCHON و مهندسان فنی میتوانند خدمات دستگاه را در کشور شما ارائه دهند.

4. کل دستگاه به مدت 1 سال گارانتی دارد. در طول دوره گارانتی، قطعاتی که به طور مصنوعی آسیب ندیدهاند. ما آن را به صورت رایگان با یک قطعه جدید برای شما جایگزین خواهیم کرد. گارانتی پس از ارسال دستگاه و دریافت بارنامه شروع میشود.

5. ما پشتیبانی فنی مادامالعمر ارائه خواهیم داد و لوازم جانبی را به طور مداوم ارائه خواهیم داد.