-

دستگاه بسته بندی کیسه

-

دستگاه بسته بندی گرانول

-

دستگاه بسته بندی مایعات

-

دستگاه بسته بندی پودر

-

دستگاه بسته بندی Mini Doypack

-

دستگاه بسته بندی چای کیسه ای

-

دستگاه بسته بندی قهوه

-

دستگاه بسته بندی عمودی

-

دستگاه بسته بندی جریان

-

دستگاه بسته بندی کیسه ای ایستاده

-

دستگاه بسته بندی وکیوم روتاری

-

ماشین پر کننده

-

دستگاه بسته بندی Doypack افقی

-

کیف از پیش ساخته شده

-

لوازم جانبی دستگاه بسته بندی

-

ماشین پر کردن و پوشاندن

دستگاه بسته بندی: ماشین وزن کامل خودکار برای کیسه های پلاستیکی از مواد ذرت نازک

| تایپ کنید | دستگاه بسته بندی اتوماتیک | نام محصول | دستگاه بسته بندی چند ایستگاه گرانول غذا |

|---|---|---|---|

| ابعاد (L*W*H) | L1900*W1400*H1450 | وزن (کیلوگرم) | 1300 |

| ولتاژ | 110V 220V 380V 50Hz/60Hz | ظرفیت تولید | 20 کیف در دقیقه ، 50 کیف در دقیقه ، 30 کیف در دقیقه |

| برجسته کردن | دستگاه بسته بندی دانه کاملا اتوماتیک,دستگاه بسته بندی کیسه های پلاستیکی از پیش ساخته شده,دستگاه ترازو و بسته بندی دانه های نازک,pre-made plastic bag packaging machine,fine-grain weighing packing machine |

||

| نوع دستگاه بسته بندی | |

|---|---|

| دستگاه بسته بندی دانه ها | |

| دستگاه بسته بندی مایع | |

| دستگاه بسته بندی پودر | |

| دستگاه بسته بندی کیف ایستاده | |

| دستگاه بسته بندی عمودی | |

| دستگاه بسته بندی افقی | |

| دستگاه کیسه چای | |

| دستگاه بسته بندی دانه قهوه | |

| دستگاه بسته بندی افقی |

دستگاه بستهبندی: دستگاه بستهبندی توزین و کیسهبندی تمام اتوماتیک برای مواد ریزدانهبندی شده، کیسههای پلاستیکی از پیش ساخته شده

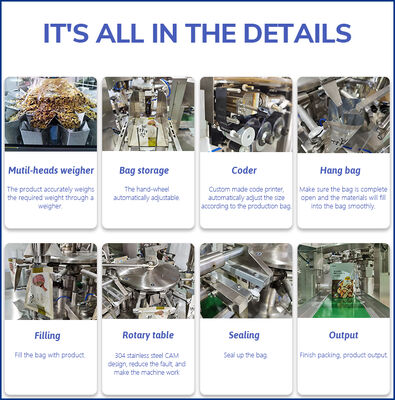

دستگاه بستهبندی شکر سفید هشت ایستگاهی یک تجهیزات بستهبندی با سرعت متوسط تا زیاد است که بهطور خاص برای توزین، پر کردن و آببندی خودکار شکر سفید طراحی شده است. این دستگاه به طور گسترده در صنایع تصفیه شکر و فرآوری مواد غذایی استفاده میشود.

I. مفهوم اصلی

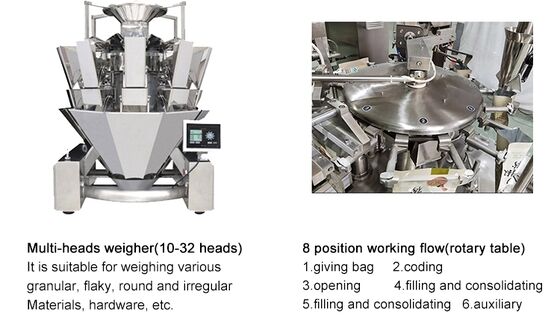

«هشت ایستگاه» به هشت ایستگاه توزین یا بستهبندی یکسان روی دستگاه اشاره دارد. این ایستگاهها مانند پرههای چرخ حول یک شفت اصلی (صفحه گردان) میچرخند و وظایف مربوطه خود را به ترتیب انجام میدهند. این طراحی، از طریق عملکرد موازی، سرعت بستهبندی را به میزان زیادی افزایش میدهد و معمولاً به 1200-2000 کیسه در ساعت یا حتی بیشتر میرسد.

II. ویژگیهای اصلی

1. راندمان بالا: با هشت ایستگاه که همزمان کار میکنند (به عنوان مثال، یک ایستگاه تغذیه، یک ایستگاه توزین، یک ایستگاه تخلیه و یک ایستگاه آببندی)، سرعت بسیار بیشتر از تجهیزات تک ایستگاهی یا دو ایستگاهی است.

2. دقت بالا: با استفاده از یک سنسور با دقت بالا و مقیاس چند سر کنترل شده توسط کامپیوتر برای تغذیه، دقت توزین بالا است، معمولاً در محدوده ±0.5 گرم قابل کنترل است و با مقررات بستهبندی کمی ملی مطابقت دارد.

3. درجه بالایی از اتوماسیون: از تغذیه، اندازهگیری، ساخت/باز کردن کیسه، پر کردن، آببندی تا کدگذاری، کل فرآیند کاملاً خودکار است و وابستگی به نیروی کار دستی را کاهش میدهد.

4. قابلیت کاربرد گسترده: قادر به بستهبندی اندازههای مختلف شکر دانهبندی شده، مانند کیسههای کوچک یا متوسط 500 گرمی، 1 کیلوگرمی، 2 کیلوگرمی و 5 کیلوگرمی.

5. پایداری خوب: ساختار مکانیکی بالغ، قابلیت عملکرد مداوم قوی، مناسب برای تولید انبوه.

III. گردش کار معمولی (با در نظر گرفتن بستهبندی عمودی کیسه از پیش ساخته شده به عنوان مثال)

1. تغذیه: شکر دانهبندی شده از طریق بالابر وارد قیف بافر و قیف توزین مقیاس چند سر کنترل شده توسط کامپیوتر میشود.

2. اندازهگیری دقیق: سیستم مقیاس چند سر مقیاس چند سر به سرعت ترکیب بهینه را محاسبه میکند و وزن دقیق شکر را از طریق سرسره راهنما وارد سیلندرهای اندازهگیری هشت ایستگاه چرخشی روی دستگاه بستهبندی میکند.

3. بازیابی و باز کردن کیسه: بازوی رباتیک کیسههای پلاستیکی از پیش ساخته شده را از مجله کیسه بازیابی میکند و دهانه کیسه را باز میکند. هر ایستگاه با یک کیسه مطابقت دارد.

4. پر کردن: صفحه گردان میچرخد. هنگامی که سیلندر اندازهگیری حاوی شکر به موقعیت پر شدن میرسد، شیر باز میشود و شکر وارد کیسه زیر میشود.

5. آببندی: صفحه گردان به چرخش به موقعیت آببندی حرارتی یا آببندی درز ادامه میدهد.

6. خروجی: کیسههای آببندی شده برای شمارش، کدگذاری (مانند تاریخ تولید، شماره دسته) یا بستهبندی در جعبه روی نوار نقاله رها میشوند.

IV. اجزای اصلی سیستم

1. سیستم بالابر و تغذیه: شکر را وارد قیف توزین میکند.

2. مقیاس ترکیبی کامپیوتری با دقت بالا: این برای دقت و سرعت بسیار مهم است. معمولاً دارای 8، 10 یا 14 مقیاس است و با یک واحد اصلی هشت ایستگاهی جفت میشود.

3. واحد اصلی چرخشی هشت ایستگاهی: محرک اصلی، مسئول نگه داشتن کیسه، پر کردن و سایر اقدامات.

4. سیستم ساخت یا برداشت کیسه: با توجه به استفاده از فیلم رول یا کیسههای از پیش ساخته شده پیکربندی شده است.

5. سیستم آببندی حرارتی/دوخت: کیسههای پلاستیکی را آببندی میکند.

6. سیستم کنترل: PLC (کنترلکننده منطقی قابل برنامهریزی) + رابط انسان و ماشین صفحه لمسی، عملکرد هماهنگ کل دستگاه را کنترل میکند، امکان تنظیم پارامترها، نظارت بر وضعیت و محاسبه خروجی را فراهم میکند.

7. سیستم انتقال و کدگذاری: محصولات نهایی را منتقل میکند و کدگذاری را انجام میدهد.

مشخصات دستگاه:

| مورد | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| بستهبندیسرعت | حداکثر 60 کیسه در دقیقه، بسته به کیفیت فیلم بستهبندی، مواد بستهبندی، وزن بستهبندی و غیره. | ||

| اندازه کیسه | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| نوع کیسه | کیسههای از پیش ساخته شده، کیسه ایستاده، کیسه مهر و موم شده چهار طرفه، کیسه مهر و موم شده سه طرفه کیسه، کیسه با شکل خاص | ||

| محدوده توزین | 10g-1kg | 10g-2kg | 10g-3kg |

|

اندازهگیری دقت |

*≤±0.5~1٪، بسته به تجهیزات اندازهگیری و مواد. | ||

| حداکثر عرض کیسه | 200mm | 250mm |

300mm |

| مصرف گاز | 0.8Mpa 0.3m3/min (تامین شده توسط کاربر) | ||

| کل پودر/ولتاژ | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| کمپرسور هوا | کمتر از 1CBM نیست | ||

| ابعاد | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| وزن دستگاه | 1300kg | 1400kg | 1500kg |

| جریان کار | دادن کیسه→کدگذاری→باز کردن کیسه (یا باز کردن کیسه زیپ)→پر کردن→ کمکی→اگزوز→آببندی حرارتی→شکلدهی و تولید محصولات. | ||

| دامنه قابل اجرا | نوع دانهای: گلوتامات سدیم کریستالی، داروی دانهای، کپسول، بذرها، مواد شیمیایی، شکر، عصاره مرغ، تخمه آفتابگردان، آجیل، آفتکش، کود و غیره | ||

(ما میتوانیم خدمات سفارشی انحصاری را با توجه به نیازهای شما ارائه دهیم!)

![]()

![]()

![]()

![]()